|

| November 27, 2018 | Volume 14 Issue 44 |

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

New mechanical and automation components help build the next generation of service robots

THK is helping manufacturers overcome some of the critical challenges to meeting the demand for advanced service robots.

Until recently, the notion of a robot mowing the lawn or delivering a toothbrush to a hotel room might have seemed like the stuff of science fiction. But thanks to a convergence of emerging technologies and market forces, robots are making their way into everyday life -- and creating new opportunities for robotics manufacturers.

PricewaterhouseCoopers (PwC) points to several factors setting the stage for "radical growth" in the service-robot industry: continuous technological innovation; wider awareness and acceptance of robotics applications; rising costs for human service labor; and the emergence of modular, open-source software platforms.* But manufacturers still face a number of technical hurdles when delivering on the promise of service robots. Those hurdles include improving manipulation capability, ensuring human safety, making robots simpler to use, and reducing the cost and size of robots.

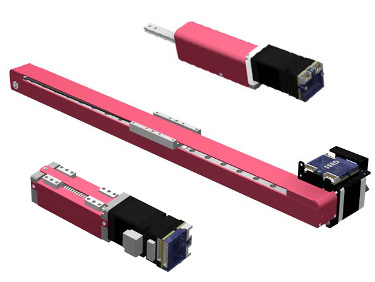

Mechanical and automation components from THK's Seed Solutions broad portfolio are driving progress in advanced service robotics on several fronts. The miniaturized actuators and operating devices fit neatly inside robots.

THK, a pioneer in linear motion guide technology, is helping manufacturers overcome some of the critical challenges to meeting the demand for advanced service robots. Building on its groundbreaking linear-motion technology that has been a catalyst for innovation in manufacturing, medicine, security, construction, and other fields, THK recently developed a set of components to help shape the future of medical robotics. Collectively known as Seed Solutions, the technology includes actuators, an operating system, sensors, and network communications capability. Increasingly, manufacturers, designers, and researchers are leveraging Seed Solutions to accelerate their efforts to develop the next generation of service robots.

Seed Solutions is driving progress in advanced service robotics on several fronts. The miniaturized actuators and operating devices fit neatly inside the robot, eliminating the need for the large external control boxes commonly used to operate conventional robots. The programs governing the robot's movements are stored inside as well, enabling the robot to move independently. Also, the modular design of the robotic systems provides a simpler and more efficient way to build the right robot for the task.

In addition to Seed Solutions, THK's portfolio of rotary actuators and components is playing a key role in developing the next wave of advanced service robots.

THK Micro Cross-Roller Ring RAU.

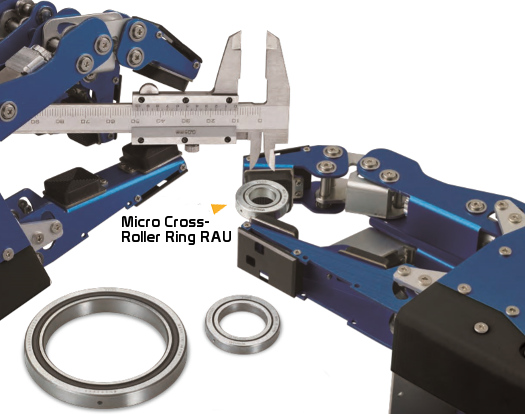

For example, robotics makers are specifying the THK Micro Cross-Roller Ring RAU (ID = 10 mm, OD = 21 mm) as a cost-effective alternative to conventional angular contact ball bearings.

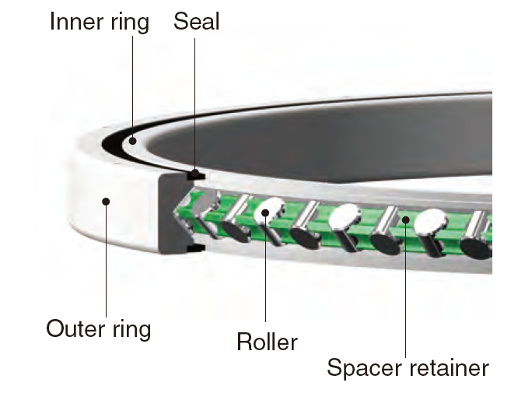

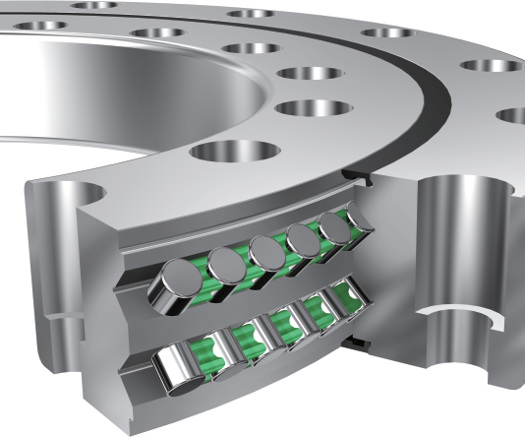

The Cross-Roller Ring is a roller bearing with high rotation accuracy capable of bearing loads in every direction. Because it has orthogonally arranged cylindrical rollers, it can bear loads in every direction. Because one cross-roller ring provides more rigidity than a double-row angular contact ball bearing -- in a more compact package -- the THK Cross-Roller Ring enables manufacturers to produce smaller, lighter robots, while reducing their machine tolerances and simplifying procurement.

The Micro Cross-Roller Ring RAU features orthogonally arranged cylindrical rollers

The RAU and other THK components -- such as the Double-Row Angular Contact Roller Ring RW -- offer another key advantage. Because of their integrated design structure, the inner and outer rings have mounting holes. They allow the component to be directly mounted to the machine without a presser flange, saving time and money on installation and labor.

THK Double-Row Angular Contact Roller Ring.

Since its inception in 1971, THK has been leveraging original technology and inventive ideas to transform the products and processes that propel human progress. In keeping with its legacy as an innovator and a trailblazer, THK is working closely with the R&D facilities, government agencies, and OEMs that are developing the next generation of robo tech.

With its core components and systems that enhance performance while reducing the size and cost of finished units, THK is helping to bring the next generation of advanced robots out of factory cages and into homes, offices, hospitals, and hotels around the world.

Learn more by reading the following from THK:

- What the Rise of Robotics Means for Engineers

- Setting the Standards for Industrial Robotics

- Seed Solutions and THK: Driving Progress in Medical Robotics

These and more are available in the THK Resource Center.

* "Service Robots: The Next Big Productivity Platform," Vinod Baya and Lamont Wood, PwC, 2015

Source: THK

Published November 2018

Rate this article

View our terms of use and privacy policy